Linen damage is one of the most common and costly problems in commercial laundry operations. Whether you’re managing a hotel, hospital, or aged care facility, ensuring your linen stays in top condition is vital for maintaining professionalism, hygiene, and guest satisfaction.

Unfortunately, many businesses end up spending more than necessary on linen replacements not because of wear and tear from usage, but due to damage caused during washing, drying, or handling. The good news? Most of this damage is preventable.

Here’s how to protect your investment and get the longest life out of your linen stock.

1. Sort Linen Properly Before Washing

Proper sorting is the first and one of the most important steps in preventing linen damage. In commercial laundry environments, it’s not enough to separate whites from colors; you also need to sort items based on fabric type, soil level, and purpose. Washing heavy or heavily soiled items with lighter or more delicate fabrics can lead to abrasion, fiber weakening, and even tearing.

For example, mixing towels with fine bedsheets can cause unnecessary friction and lint transfer. Sorting also allows detergents to work more effectively and ensures that delicate fabrics receive gentler wash cycles. By taking a few extra minutes to sort properly, you protect your linen investment and improve the overall quality of the wash.

2. Use the Right Detergents and Chemicals

Harsh or inappropriate chemicals are a major cause of fiber damage. While industrial-strength detergents are necessary for sanitation, they must be carefully selected based on:

- Fabric type

- Level of staining

- Water hardness

Overuse of bleach or strong alkalis can weaken fibers over time. Enzyme-based or pH-balanced solutions are often better choices for longevity.

A professional linen service provider like SPL ensures chemical usage is optimized for both cleaning performance and fabric preservation, so clients don’t have to worry about the details.

3. Watch the Water Temperature

High temperatures might clean faster, but they also break down fibers and cause shrinkage. In fact, one of the most common reasons for early linen wear is washing or drying on the wrong heat settings.

Use machine settings specific to the fabric type. Always follow manufacturer guidelines and avoid unnecessary heat exposure during both washing and drying.

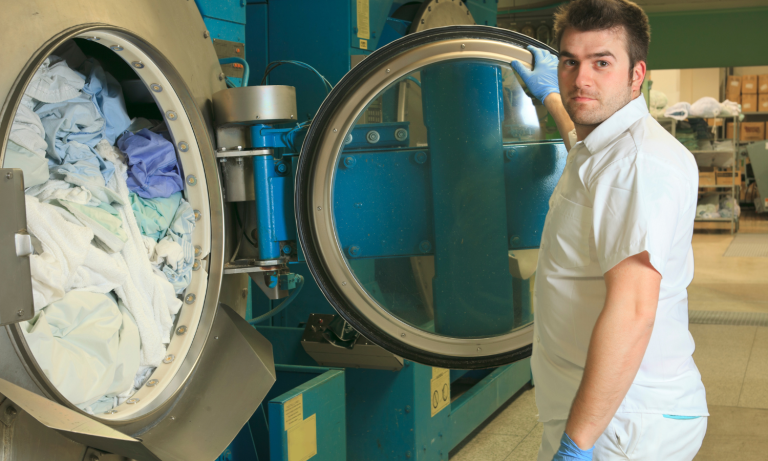

4. Avoid Overloading Machines

It’s tempting to maximize every load to save time or reduce energy costs, but overloading is counterproductive. When machines are too full:

- Detergent and water can’t circulate properly

- Mechanical stress on linen increases

- Dirt can redeposit on “clean” items

Stick to the recommended load capacity. Underloading isn’t efficient either, so finding the right balance is key.

5. Train Staff on Proper Handling

Human error during handling both before and after washing is another common source of damage. Train your team to:

- Avoid dragging linen on the floor

- Never use damaged carts or rough-surfaced containers

- Fold items with care to avoid stretching seams

Simple habits like removing items immediately after drying can also prevent set-in wrinkles and fiber weakening due to over-drying.

6. Regularly Maintain Laundry Equipment

Laundry equipment that isn’t properly maintained can create hidden damage. A rusted drum or broken gasket may not seem like a big issue, but over time it can tear linens, leave stains, or cause uneven washing.

Schedule regular maintenance and inspections to ensure your machines are operating safely and efficiently.

7. Use Linen Inventory Rotation

Using the same set of linens repeatedly while others stay in storage leads to uneven wear. A simple inventory rotation system (like FIFO, First In, First Out) ensures every item gets equal usage time.

Overused linens wear out faster, while underused ones age and degrade in storage. Balance is key.

Conclusion

Preventing linen damage isn’t just about having clean laundry, it’s about protecting an asset. Whether it’s sheets, towels, or uniforms, every item has a replacement cost, and every damage has a reason behind it. By following the right processes, using the proper equipment, and partnering with a reliable provider like SPL, businesses can extend the life of their linen, reduce waste, and save money in the long run.

Want to safeguard your linen investment? Start with the right practices and the right partner.